So, you’ve decided to level up your workshop with a CNC laser cutting machine. Whether you’re creating custom signs, engraving designs, or running a small production shop, investing in the right laser cutter can seriously boost your creativity and productivity.

But let’s be honest—it’s a big purchase. With so many options, features, and technical specs to consider, how do you know you’re making the right choice?

No worries—this complete guide will break it down in plain English, with technical tips, insider advice, and real-world examples to help you make a smart buy. 💡

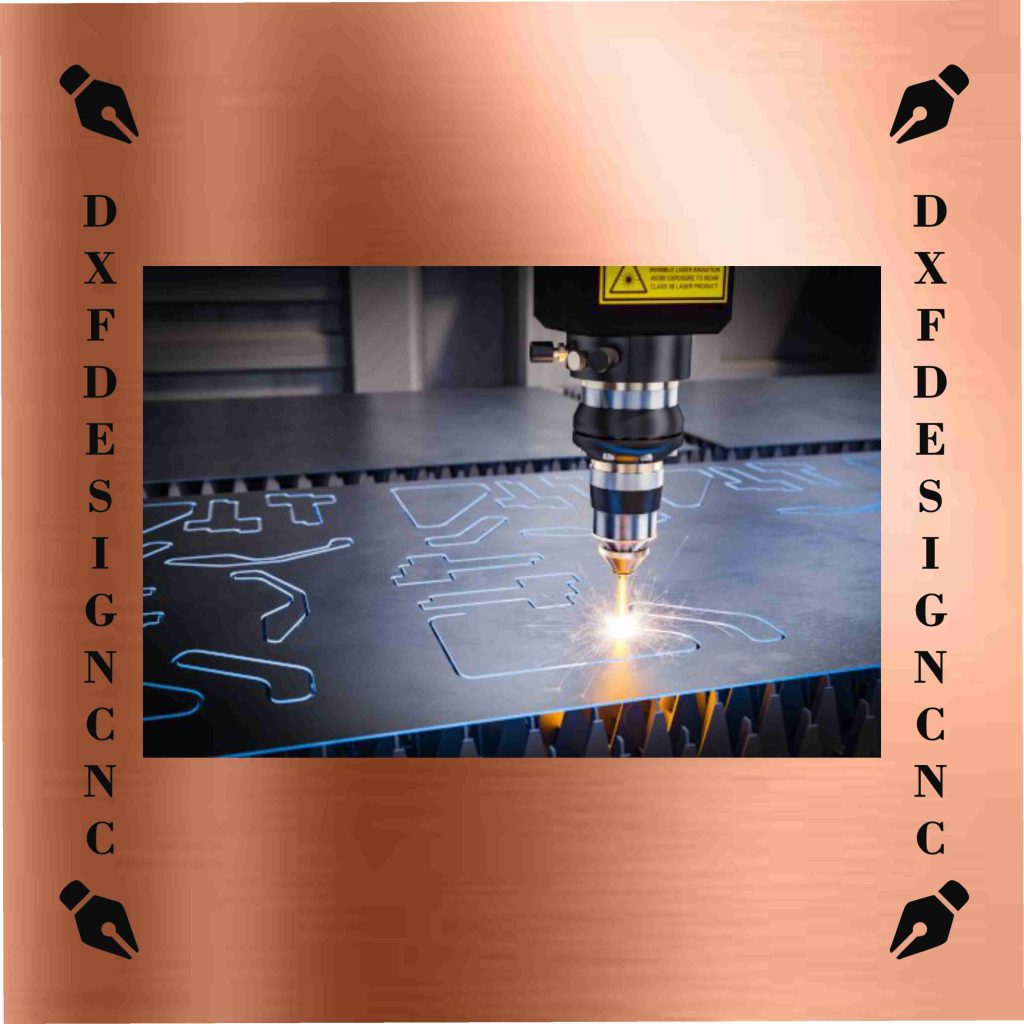

✨ What is a CNC Laser Cutter?

A CNC laser cutting machine uses a focused laser beam to cut, engrave, or etch a wide range of materials with extreme precision. “CNC” stands for Computer Numerical Control, meaning the machine follows programmed commands to move the laser exactly where it needs to go.

🔍 Step 1: Understand Your Needs

Before shopping, ask yourself:

- What kind of projects will you be doing?

- What materials will you cut or engrave? (Wood, acrylic, metal, leather, etc.)

- How thick are those materials?

- Will you use it for personal, hobby, or commercial use?

- What’s your budget?

🎯 Pro Tip: A hobbyist needs a totally different machine than someone running a busy shop. Don’t overspend or underspend based on the wrong assumptions.

🧪 Step 2: Know the Types of Laser Technologies

There are 3 main types of laser sources used in CNC machines:

1. CO₂ Lasers

- Best for: Wood, acrylic, glass, leather, plastics, fabric

- Power: Typically 40W to 150W

- Affordable and versatile

- Not great for metals without special coatings

2. Fiber Lasers

- Best for: Metal (stainless steel, aluminum, copper, brass, etc.)

- High precision, super fast

- Long lifespan (up to 100,000 hours!)

- More expensive but ideal for industrial metal work

3. Diode Lasers

- Best for: Light-duty engraving on wood, leather, some plastics

- Compact, budget-friendly

- Lower power, not ideal for cutting thick materials

🧰 Step 3: Technical Specs That Actually Matter

Let’s break down the essential features you should consider before buying.

🔋 1. Laser Power (Watts)

The higher the wattage, the deeper and faster you can cut.

| Material | Suggested Power |

|---|---|

| Paper/Fabric | 40W |

| Wood/Acrylic | 60W–100W |

| Metals | 100W+ (Fiber) |

🔥 Tip: If you’re mostly engraving, you don’t need high wattage. If you’re cutting thicker material, aim higher.

📏 2. Working Area Size

Think about the maximum size of your workpieces. Common bed sizes:

- 300×200 mm (small)

- 600×400 mm (mid-range)

- 1300×900 mm or more (large-scale)

🧠 Bigger bed = larger projects but also takes up more space and costs more.

⚙️ 3. Motion System & Precision

- Linear rails vs belt drive – Linear rails are smoother and more accurate.

- Stepper vs Servo Motors – Servo motors are more expensive but give higher precision and feedback.

🔍 Look for:

- Repeatability (how accurately it returns to the same position)

- Speed (mm/s or inches/min)

- Positioning accuracy (usually in microns or millimeters)

🌬️ 4. Cooling System

Lasers get hot—especially CO₂ lasers.

- Small machines might use air cooling

- Bigger ones often need water cooling (chillers)

💡 Tip: Don’t skimp on cooling. A proper chiller can extend your laser’s lifespan.

🛡️ 5. Safety Features

- Emergency stop button

- Protective covers or enclosures

- Laser class rating

- Proper exhaust/ventilation

⚠️ If you’re working indoors or at home, safety isn’t optional—it’s a must.

🧪 Step 4: Software Compatibility

Most machines come with their own control software, but also check if they support:

- LightBurn (popular for CO₂ lasers)

- RDWorks, EZCAD, GRBL, or Mach3

✔️ Make sure your system supports vector formats like DXF, SVG, AI, CDR, etc.

Also confirm it runs on your OS (Windows, macOS, or Linux).

🧱 Step 5: Build Quality

Inspect or read reviews about:

- Frame material (steel vs aluminum vs plastic)

- Gantry quality

- Wiring and cable management

- Lens and mirror quality (for CO₂)

A solid frame = more stable, more precise, and fewer issues long-term.

💻 Step 6: Customer Support & Community

Let’s face it—things go wrong. Machines act up.

You’ll want:

- Active online communities (forums, YouTube)

- Responsive customer support

- Availability of spare parts or accessories

🧠 Choose a brand with a reputation for helping their customers, not ghosting them after the sale.

💸 Step 7: Budgeting (Don’t Forget Hidden Costs)

🧾 Base Machine Cost

- Diode Laser: $200–$600

- CO₂ Laser: $800–$5,000

- Fiber Laser: $4,000–$20,000+

💡 Extras You’ll Likely Need

- Laser safety glasses

- Air assist

- Exhaust fan or filter

- Water chiller (for CO₂)

- Replacement lenses/mirrors

- Honeycomb bed

Don’t forget shipping fees, import taxes, and possibly assembly time.

🚚 Where to Buy?

✅ Trusted Places:

- Official manufacturer websites (like OMTech, Thunder Laser, Gweike, xTool)

- Authorized distributors

- Amazon or AliExpress (be cautious—check reviews!)

- Local dealers or resellers (helpful for support)

🤖 Bonus: CNC Laser vs CNC Router – Know the Difference

| Feature | CNC Laser | CNC Router |

|---|---|---|

| Cutting Method | Heat (laser beam) | Mechanical (rotating bit) |

| Best For | Engraving, thin cuts | Deep carving, thick material |

| Precision | Extremely high | High |

| Noise | Quieter | Louder |

| Dust/Particles | Less (mostly smoke) | More dust & chips |

✅ If you want to engrave intricate designs, a laser cutter is your best bet.

🛠️ Real Use Case Examples

- A small business selling custom wood signs might go for a 100W CO₂ laser with a 600×900 mm bed and LightBurn compatibility.

- A metal fabrication shop should invest in a fiber laser with high wattage and servo motors.

- A DIY crafter could start with a 10W diode laser under $500 to engrave wood, leather, and acrylic.

🔚 Final Checklist Before You Buy

✅ Do I know what materials and thickness I’ll work with?

✅ Is the laser type (CO₂, fiber, diode) right for my use case?

✅ Is the machine powerful enough for my needs?

✅ Does it come with necessary cooling/safety features?

✅ Is it compatible with my software and file types?

✅ Can I get support or spare parts easily?

✅ Does my workspace have proper ventilation and power?

🧠 Final Thoughts

Buying a CNC laser cutter is an exciting step, but it’s not a decision to rush. The right machine can unlock massive creative and business potential, while the wrong one can become an expensive paperweight.

Do your research, ask questions, and invest in a machine that aligns with your goals. Trust me, future-you will thank you. 🙌